Нейлоновую ткань можно встретить практически повсюду в индустрии сумок: в утренних автобусах, в кафе во время обеденного перерыва и у оживленных выходов на посадку в аэропортах. Если вы оглянетесь вокруг, то заметите ее присутствие в самых разных формах: от городских сумок в руках деловых людей до легких рюкзаков на плечах студентов и многофункциональных походных сумок, которые носят любители активного отдыха. Этот, казалось бы, обычный материал, в отличие от кожи, которая «деликатная», или холста, который «тяжелый», незаметно стал «универсальным» материалом в мире сумок благодаря своим комплексным качествам: «легкость, прочность, водонепроницаемость и простота в уходе».

I. Определение нейлоновой ткани.

Нейлон, научно известный как полиамидное волокно, — это текстильная ткань, изготавливаемая из полиамида в качестве основного сырья с помощью таких процессов, как экструзионная обработка расплава, окрашивание, ткачество и отделка. Это первое в мире волокно, полностью синтезированное химическим путем.

Нейлон был изобретен американским ученым Уоллесом Кэротерсом в 1935 году и первоначально использовался в качестве заменителя шелка при производстве женских чулок. Во время Второй мировой войны, благодаря своей исключительной прочности и долговечности, он широко использовался в военной экипировке, включая парашюты, палатки и военные рюкзаки. Именно в этот период были полностью подтверждены превосходные характеристики нейлона в различных областях, что заложило основу для его последующего выхода на рынок гражданских сумок.

II. Технические характеристики нейлоновой ткани.

1. Классификация по толщине пряжи

Это наиболее важная характеристика, измеряемая в денье, которая обозначает вес в граммах 9000 метров пряжи. Чем выше число денье, тем толще пряжа, и тем тяжелее и прочнее ткань.

- Сверхлегкий: Ткань 10D-30D, относящаяся к ультратонкому диапазону плотности, с плотностью всего 15–45 г/м², не обладает достаточной прочностью, чтобы самостоятельно выдерживать вес. Обычно её покрывают функциональными слоями или комбинируют с другими тканями. После нанесения функциональных покрытий её можно использовать в качестве подкладки для спальных мешков, материалов для палаток или дождевых чехлов для рюкзаков.

- Легкий вес: Ткань плотностью 40D-70D, на ощупь похожа на шелк, прочность на разрыв составляет 5-6 Н, поэтому легко рвется при зацеплении в местах приложения нагрузки. Подходит только для... сверхлегкие складные сумки или подкладочные мешочки, и требует полиуретанового покрытия, при этом все точки напряжения должны быть усилены тесьмой и армирующими тканями.

- Средний вес: В индустрии производства сумок ткань 210D-420D относится к «золотому диапазону средней плотности», обеспечивая достаточную прочность, умеренную стоимость и широкий спектр применения. Практически все производители используют эту спецификацию. Ткань 210D обычно используется для сумок на завязках, а 420D — почти повсеместно применяется во всех типах сумок, включая рюкзаки, дорожные сумкии многое другое.

- Тяжеловесы: 500D-1000D и выше, используется в областях, требующих исключительной износостойкости.

Например, ткань Cordura 1000D обычно используется для днищ и зон с высоким трением в тактических рюкзаках и сумках для инструментов. Ткань 1680D используется для изготовления высококачественных корпусов для багажа.

2. Классификация по плотности ткани

Единица измерения — «TEX», которая обозначает общее количество нитей основы и утка на дюйм и отражает плотность ткани. Чем выше число TEX, тем плотнее ткань и тем лучше ее ветро- и водонепроницаемые свойства.

- Низкая плотность: 70T-150T, воздухопроницаемый, используется для палаток, зонтов и т. д.

- Средняя плотность: 190T-290T — материал, обеспечивающий баланс между прочностью и легкостью, используется для рюкзаков и одежды.

- Высокая плотность: Ткань плотностью 300-470T, плотная и прочная, используется для изготовления высококачественного багажа и защитной одежды.

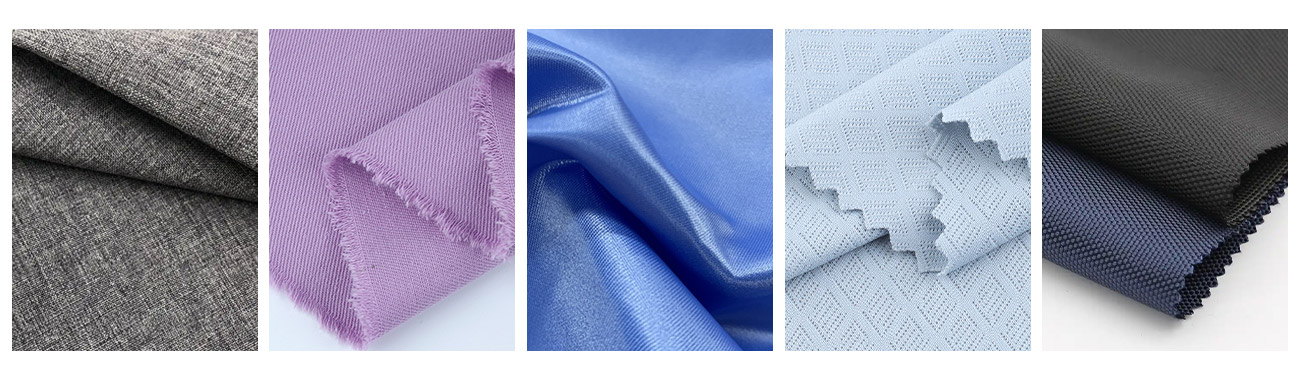

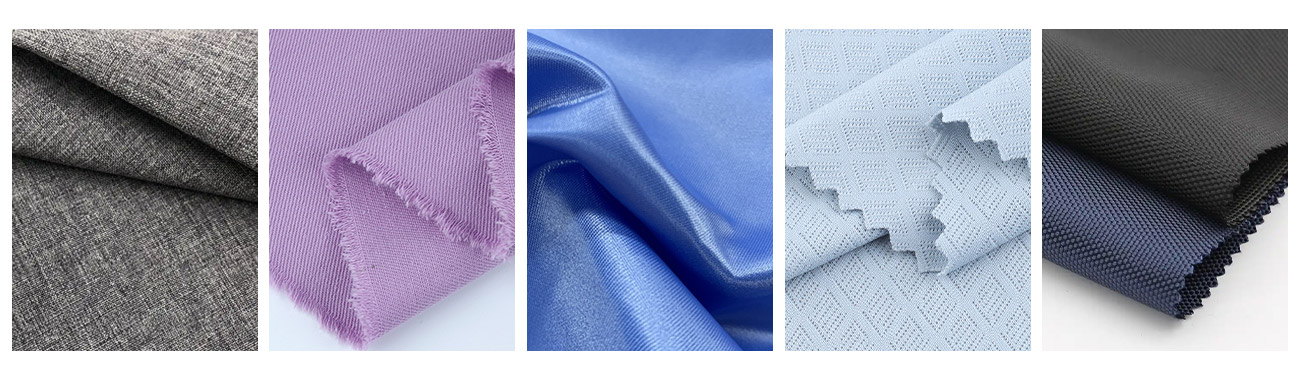

3. Классифицируется по рисунку плетения.

Пряжа изготавливается различными методами путем плетения, в результате чего образуется ткань, а способ плетения определяет внешний вид и свойства ткани.

- Простое переплетение: Техника, при которой нити основы и утка переплетаются через одну нить, что приводит к плотной структуре и легкой текстуре; широко используется для тканей для пуховых курток.

- Саржевое переплетение: Поверхность ткани имеет отчетливые диагональные линии, обеспечивающие хорошую износостойкость, и обычно используется для изготовления багажа.

- Атласное плетение: Поверхность ткани гладкая и блестящая, но склонна к зацепкам, обычно используется для высококачественной одежды или подкладок.

- Жаккардовое переплетение: Текстиль, созданный на жаккардовом станке, который контролирует переплетение нитей основы и утка, непосредственно формируя рельефные узоры, обладающие высокой декоративностью и используемые для производства высококачественной продукции.

- Оксфордская ткань: В основе и утке этой ткани используется сочетание грубых и тонких нитей, что придает ей текстурированную поверхность. Она прочная и износостойкая, широко используется для изготовления рюкзаков, палаток и многого другого.

4. Классификация по процессу финишной обработки.

Именно этот процесс придает ткани ее окончательную функциональность. Одна и та же базовая ткань, обработанная по-разному, может иметь совершенно разные эксплуатационные характеристики.

- Полиуретановое покрытие: Водонепроницаемый, износостойкий, приятный на ощупь.

- ПВХ-покрытие: Водонепроницаемость, хорошая устойчивость к атмосферным воздействиям и низкая стоимость.

- Покрытие из ТПУ/ТПЭ: Экологически чистый, воздухопроницаемый и гибкий.

- Водоотталкивающее покрытие: Прочное водоотталкивающее покрытие, благодаря которому капли воды скатываются с поверхности.

- Огнезащитное покрытие: Огнестойкий и огнезащитный, используется для специальных защитных целей.

- УФ-стойкое покрытие: Предотвращает солнечные ожоги и старение ткани.

- Антибактериальное покрытие: Предотвращает появление неприятных запахов, плесени и обеспечивает гигиену.

- Влагоотводящее покрытие: Сохраняет кожу сухой и регулирует температуру тела.

- Антистатическое покрытие: Устраняет статическое притяжение и предотвращает статические искры.

III. Характеристики и ограничения нейлоновой ткани.

1. Характеристики;

- Высокая прочность: Его прочность в 2-3 раза выше, чем у хлопковых волокон того же веса. Он обладает хорошей упругостью и может выдерживать десятки тысяч изгибов, не разрываясь.

- Износостойкость: Его износостойкость в 10 раз выше, чем у хлопка, и в 20 раз выше, чем у шерсти, что делает его широко используемым в изделиях, требующих высокой износостойкости.

- Хорошая эластичность: Ткань обладает превосходной упругостью, благодаря чему она менее подвержена деформации, а её текстура остаётся гладкой.

- Легкий и компактный: Благодаря плотности всего 1,15 г/см³, она весит в 3 раза меньше кожи и в 2 раза меньше холста. Сумка для 15-дюймового ноутбука может уменьшить вес на 180-220 г, значительно снизив нагрузку на плечи во время поездок на работу.

- Быстро сохнет и легко чистится: На открытом воздухе высыхает за 30 минут, снижая риск образования плесени. Поверхность не требует особого ухода, кофе или тональный крем легко удаляются.

- Базовая гидроизоляция: Само волокно обладает коэффициентом влагопоглощения . <4%. После нанесения специальных полиуретановых/тетрауретановых покрытий или ламинирования его водонепроницаемость может достигать более 800 мм вод. ст.

- Высокая насыщенность красителя: Можно окрашивать кислотными красителями при низкой температуре 95 °C, достигая разницы в цвете ΔE.<0,8, в отличие от полиэстера, для производства которого требуются высокая температура и высокое давление.

2. Ограничения;

- Плохое впитывание влаги: Ткань плохо пропускает воздух и склонна к образованию статического электричества.

- Склонен к образованию катышков: После длительного трения на поверхности могут образовываться катышки.

- Средняя термостойкость: Она легко размягчается при высоких температурах (температура плавления около 215-260°C) и требует низкой температуры для глажки.

IV. Применение нейлоновой ткани в производстве сумок.

Благодаря своей исключительной прочности, износостойкости, легкости и универсальности, нейлоновая ткань создала высокоразвитую и взаимосвязанную производственную цепочку в индустрии сумок. В плане сценариев применения, возможности нейлоновой ткани по охвату всех областей полностью продемонстрированы.

1. Сценарии ежедневных поездок на работу и деловых поездок

Основные требования: лёгкий, прочный, легко чистится и подходит для ежедневного частого использования.

- Рюкзаки: Вместительный, с множеством отделений, идеально подходит для студентов и профессионалов.

- Сумки для ноутбуков: Изготовлен из нейлона плотностью 420D-600D, оснащен ударопрочным отделением для ноутбука, что удобно для поездок на работу.

- Портфели/сумки через плечо: Изготовленная преимущественно из ткани плотностью 600D-900D и отличающаяся минималистичным дизайном, она сочетает в себе прочность и структурность, что делает ее подходящей для деловых мероприятий.

2. Сценарии занятий спортом на открытом воздухе и приключений

Основные требования: высокая прочность, износостойкость, водонепроницаемость и воздухопроницаемость, пригодность для сложных условий эксплуатации на открытом воздухе.

- Походные рюкзаки: Изготовлен из высокоплотного нейлона 1000D-1680D, оснащен профессиональной системой переноски.

- Трекинговые рюкзаки: Нейлон 600D-840D, с упором на легкость и воздухопроницаемость.

- Рюкзаки для трейлраннинга: Сверхлегкий нейлон 210D-420D, разработанный для плотного прилегания к телу.

- Велосипедные сумки: Водостойкий нейлон, часто оснащенный светоотражающими полосами и чехлами от дождя.

3. Сценарии деловых поездок и путешествий

Основные требования: большая вместимость, устойчивость к истиранию и царапинам, пригодность для транспортировки как на дальние, так и на короткие расстояния, а также для частого использования и организации хранения.

- Дорожные рюкзаки: Конструкция с возможностью расширения вместимости, идеально подходит для путешествий.

- Косметички и органайзеры: Водонепроницаемый нейлон, удобен для организации туалетных принадлежностей.

- Чемоданы: Изготовлен из нейлона плотностью 600D-1000D, оснащен замками, одобренными TSA.

4. Мода и трендовые сценарии

Основные требования: Продуманный дизайн, насыщенные цвета, лёгкий и модный, сочетание стиля и практичности.

- Сумки через плечо и наплечные сумки: Изготовлено из нейлона плотностью 210D-420D, с принтами или рисунками, вырезанными лазером.

- Клатчи: Легкий нейлон, идеально подходит для повседневного ношения.

- Поясные и нагрудные сумки: Легкая конструкция, идеально подходит для занятий спортом и отдыха.

5. Сценарии для студентов и кампуса

Основные требования: большая вместимость, многосекционность, высокая экономическая эффективность.

- Студенческие рюкзаки: Изготовлен из нейлона плотностью 420D-600D, оснащен множеством отделений и отсеками для канцелярских принадлежностей.

- Спортивные сумки: Легкий и дышащий материал, идеально подходит для уроков физкультуры и клубных занятий.

6. Сценарии родов и родов

Основные требования: лёгкий, безопасный, легко моющийся, с интересным дизайном.

- Сумки для подгузников: Конструкция с несколькими отделениями для удобной сортировки и хранения.

- Детские рюкзаки: Легкая конструкция, эргономичная, подходит для детского телосложения.

7. Профессиональные инструменты и специализированные сценарии

Основные требования: высокая функциональность, износостойкая защита, возможность индивидуальной настройки отсеков и защитных конструкций.

- Сумки для фотоаппаратов: Ударопрочные отсеки для защиты фотооборудования.

- Сумки для инструментов: Нейлон 1000D и выше, оснащенный системами организации и фиксации инструментов.

- Медицинские и спасательные сумки: Огнестойкий или антибактериальный нейлон, соответствующий профессиональным стандартам.

- Военные сумки: Изготовлено из баллистического нейлона или кордуры, разработано для работы в экстремальных условиях.

8. Индивидуальные и персонализированные сценарии

Основные требования: индивидуальный дизайн, персонализация бренда, ограниченная серия.

- Фирменные корпоративные сумки на заказ: Изготовлены с нанесением фирменных логотипов, используются в качестве корпоративных подарков.

- Памятные подарочные пакеты мероприятия: Дизайн разработан с учетом тематики мероприятий, доступен в ограниченном количестве.

- Персонализированные сумки на заказ: Индивидуальный дизайн с использованием различных узоров или текста.

9. Экологичные и устойчивые сценарии

Основные требования: Экологически чистые материалы, возможность вторичной переработки, устойчивое развитие.

- Сумки из переработанного нейлона: Изготовлено из переработанного нейлона.

- Биоразлагаемые нейлоновые сумки: Изготовлено из растительного сырья, что снижает выбросы углекислого газа.

- Биоразлагаемые нейлоновые сумки: Специально разработан для снижения загрязнения окружающей среды.

10. Сценарии развития интеллектуальных технологий

Основные требования: интеграция функций, интеллектуальные возможности подключения, ощущение высокотехнологичности.

- Умные рюкзаки: Встроенная система управления внешними аккумуляторами, отслеживание местоположения по Bluetooth и противоугонная система.

- Рюкзаки на солнечных батареях: Оборудован солнечными батареями для зарядки устройств.

- Водонепроницаемые сумки для электроники: Полностью водонепроницаемый, предназначен для защиты электронных устройств.

В заключение, нейлоновая ткань — это не просто синтетическое волокно, а специально разработанный материал, который эволюционировал на протяжении столетия, глубоко адаптируясь к потребностям индустрии сумок. От точной классификации основных характеристик до функциональных модификаций и усовершенствований, от своего основного преимущества — легкости — до экологических улучшений, нейлоновая ткань постоянно оптимизировалась, чтобы соответствовать требованиям к долговечности, портативности и функциональности сумок. Она стала важным мостом, соединяющим материаловедение с дизайном сумок. В следующий раз, когда вы будете носить нейлоновую сумку, остановитесь на мгновение и оцените, что в ней хранятся не только ваши личные вещи, но и легенда о материале, покорившем мир.

ПОДДЕРЖИВАЕМАЯ СЕТЬ

ПОДДЕРЖИВАЕМАЯ СЕТЬ